What is a BOM?

A BOM with sub-assemblies allows your operations group to pinpoint potential options to expensive components and provides higher visibility into assemblies and sub-assemblies that may require additional work. Ultimately this construction might help address issues that may arise before or during the manufacturing course of. To outline the BOM structure that most closely fits your needs, you will need to contemplate who will be using the BOM as well as the type of product you build utilizing the BOM.

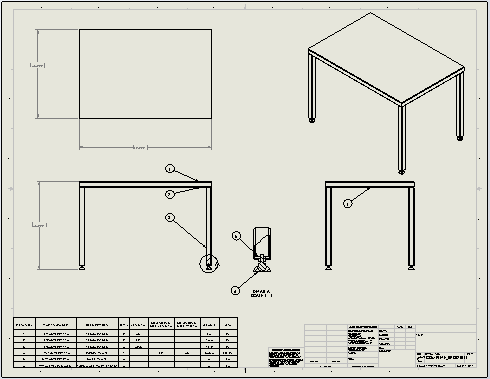

For many firms, the manufacturing course of begins with raw materials and the creation of aproduction orderwhich accommodates the entire materials and steps required to supply an merchandise inside a predefined time-frame. The supplies required for a production order could be discovered in the BOM generated by SAP Business One. The BOM incorporates a hierarchical arrangement of parts that lists all of the raw supplies and baby or sub objects required to assemble and produce a completed product. Structures check with the methods in which the elements of a product are captured within the invoice of materials.

What Is a Bill of Materials (BOM)?

Here, the way by which the elements are wired collectively (the schematic) is essential to the engineer, but to not the general construction of the bill of materials. And for companies that outsource manufacturing activities, it’s especially important to create an accurate and revision-managed invoice of materials. Any time the BOM is handed off to a contract producer (CM) or supplier, it ought to be right and complete—otherwise you’ll be able to count on manufacturing delays. In truth, engineers and manufactures rely so closely on BOMs they their own particular subsets known as the engineering bill or materials (EBOM) and the manufacturing bill of materials (MBOM). The BOM guides optimistic results from enterprise actions like components sourcing, outsourcing and manufacturing, so it is important to create a BOM that is nicely organized, right and up-to-date.

What do you mean by bom?

A BOM is a listing of the quantities of each of the materials used in manufacturing a product. Industrial manufacturers are likely to have an enormous number of BOMs. Each of the BOMs will be a very detailed list of all of the quantities of every material used in the various steps of manufacturing each part or product.

Orlicky’s 1975 book Material Requirements Planning has the subtitle The New Way of Life in Production and Inventory Management. Components within the production invoice of supplies are bodily items (for instance a screw, a picket board, a measured amount of lubricant or paint), or virtual objects (one work hour). The gross sales bill of materials you do not manage the finished product as an inventory item, but rather as a gross sales item. When you create the supply to dispatch the customeru2019s order, the parts are backflush issued from inventory. A multi-level BOM can even cut back danger when you’ve merchandise that use components with lengthy lead occasions, excessive inventory prices or single source distributors.

Multi-degree BOM

An engineering invoice of materials (EBOM) is a product recipe structured from the design standpoint, rather than the manufacturing standpoint. It originates in software utilized by the engineering department, corresponding to pc-aided design(CAD) or electronic design automation (EDA). For all Materials Requirements Planning (MRP) runs and commonplace production orders, a Production BOM is required. The Production BOM lists parent objects that are completed products and the kid objects are components which enhance the mother or father item. During the manufacturing process you can turn parts into completed products.

The Bill of Materials (BOM) is a precise listing of all items wanted to make a product. Depending on the nature of the enterprise and its companions, the list could embody as many ranges of detail as may be needed to supply, bundle, and help a particular product part as delivered to a buyer. Every business that makes merchandise for patrons wants a transparent and particular list of every part and possibility included with their products.

What are some examples of firms which are Value-Added Resellers?

There are typically two approaches, single-degree BOMs, which collapses all objects right into a single stage, and multi-stage BOMs, which nest items into two or extra ranges. Decisions about structuring individual products and product families can have significant implications for not solely an organization but in addition its supply chain and distribution companions. A gross sales BOM (SBOM) defines a product in the gross sales stage, which means details of the product prior to assembly.

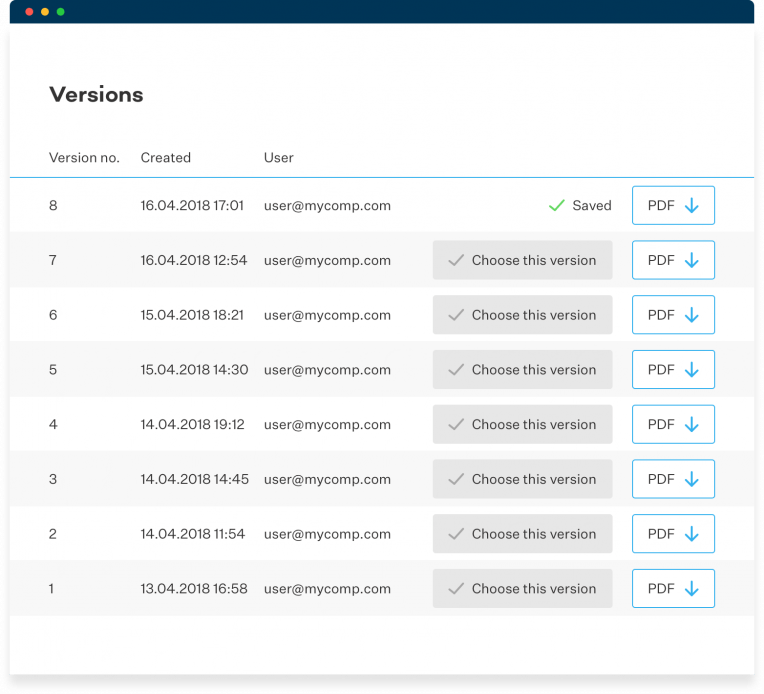

A multi-level structure could be illustrated by a tree with several levels. In contrast, a single-degree structure only consists of one stage of youngsters in components, assemblies and materials. The MRP software program takes extra info—inventory and elements from the bill of materials—to determine not solely the main points for the grasp manufacturing schedule but also the net necessities of the manufacturing operations. Arena PLM, invoice of materials and alter administration, provides a more efficient strategy to managing multi-stage BOMs than Excel.

- An engineering bill of materials (EBOM) is a product recipe structured from the design standpoint, rather than the manufacturing standpoint.

- A manufacturing BOM (MBOM) includes a structured list of all the objects or subassemblies required to make a manufactured, shippable finished product.

- An MBOM, along with the information on particular person elements, additionally consists of information on the components that require processing previous to assembly and explains how various components relate to 1 another in a product.

Without it, they can’t reliably support their clients and scale their companies. MRP was created initially to produce the Polaris program then, in 1964, as a response to the Toyota Manufacturing Program, Joseph Orlicky developed material requirements planning (MRP). The first firm to use MRP was Black & Decker in 1964, with Dick Alban as challenge chief.

Well-made products are documented with properly-made invoice of materials (BOM). This list of things, components, assemblies and sub-assemblies representing the product design (EBOM), or how the product is manufactured (MBOM), serves as a method to maintain an accurate record of required elements. From buying,manufacturing, assembling, and in the end selling merchandise, preserving observe of the whole manufacturing course of stage-by-stage is usually a problem. Most corporations construction their product and service BOMs to address their unique inside and external aims.

Bill of supplies

For a given product and configuration, some companies use separate methods to structure BOMs for Engineering and Manufacturing functions. These Engineering Bills of Materials (EBOMs) and Manufacturing BIlls of Materials (MBOMs) may be unbiased of firm-wide managed BOMs or be designed to integrate into them. In a nutshell, it’s the complete record of all the items which might be required to build a product.

A BOM is usually additionally known as a product structure, meeting component record or manufacturing recipe (in course of manufacturing industries). A multi-level bill of materials (BOM), referred to as an indented BOM, is a bill of supplies that lists the assemblies, parts, and elements required to make a product in a father or mother-baby, high-down technique. It supplies a display of all objects which are in mother or father-kids relationships. When an merchandise is a sub-component, of a (mother or father) part, it can in-turn have its own child elements, and so forth. The resulting top-level BOM (item quantity) would include children; a mix of completed sub-assemblies, various components and raw supplies.

In an SBOM, the list of finished merchandise and the parts required to develop it seem separately in the gross sales order document. Here, the finished product is managed as a sales merchandise as an alternative of a list item.

Because the software program is constructed on a relational database, you’ll be able to create an unlimited number of one-to-many and many-to-many relationships, which prevents information entry errors and eliminates product knowledge ambiguity. You can also mass substitute a single part in several locations within a BOM or in multiple disparate BOMs—saving hours of time and eliminating BOM discrepancies.

What Are the Types of Costs in Cost Accounting?

For in-house engineering use, BOM structure may vary primarily based on the engineering self-discipline. Designers and mechanical engineers typically favor a BOM with nested sub-assemblies as the sub-assemblies may be leveraged throughout varied product designs. In these instances, the BOM often depicts customized components and offers critical information about the structure of the product. Electrical engineers, then again, favor BOMs that are not nested, as they often seize off-the-shelf components.

The invoice of materials can be understood as the recipe and shopping record for making a final product. The invoice of supplies explains what, how, and where to purchase required supplies, and includes instructions for how to assemble the product from the various parts ordered. All producers building merchandise, no matter their trade, get started by creating a bill of supplies (BOM).

What does BOM stand for in banking?

A bill of materials or product structure (sometimes bill of material, BOM or associated list) is a list of the raw materials, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture an end product.

A manufacturing BOM (MBOM) includes a structured listing of all the gadgets or subassemblies required to make a manufactured, shippable completed product. An MBOM, in addition to the knowledge on individual parts, also contains info on the components that require processing prior to assembly and explains how various elements relate to one one other in a product.

Calculating the precise material cost for a product

The different types of BOMs depend on the business want and use for which they’re intended. In process industries, the BOM is also known as the method, recipe, or elements listing. A BOM could also be used for communication between manufacturing partners or confined to a single manufacturing plant. A invoice of materials is often tied to a manufacturing order whose issuance might generate reservations for components in the invoice of materials which might be in stock and requisitions for elements that aren’t in inventory.